Ferumira

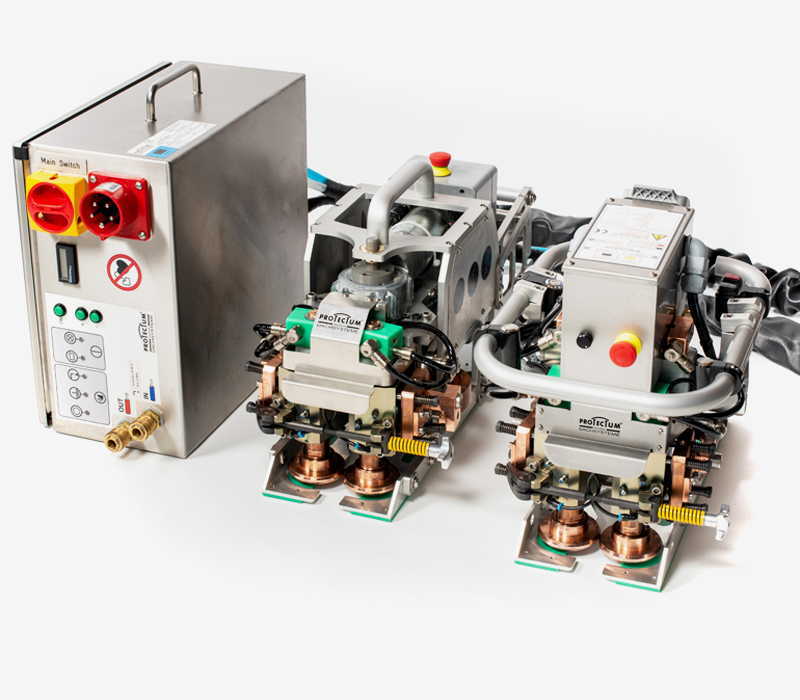

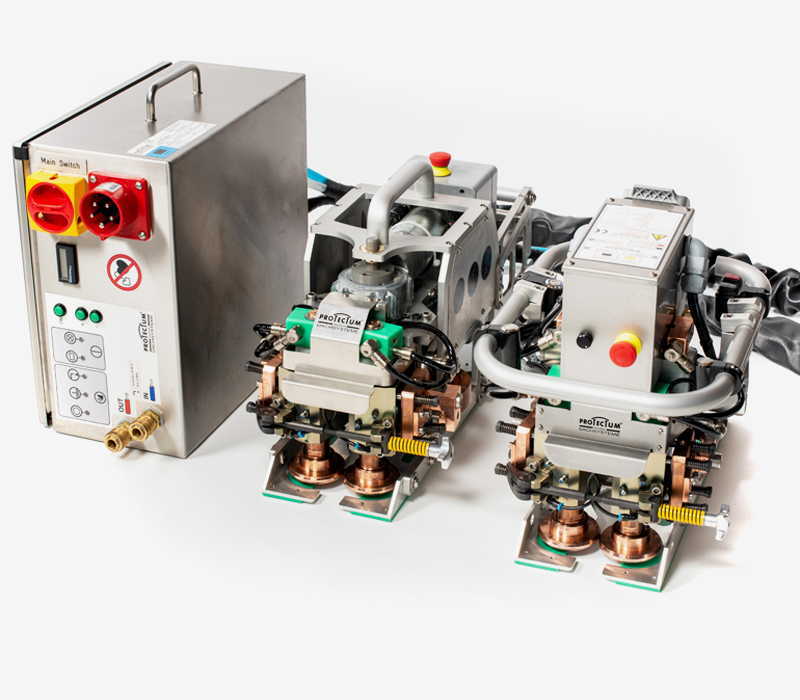

Thanks to the absolute love of the roller seam welded stainless steel roofs and 35 years of experience, in 2016 we started with series production of our Ferumira roof seam welding machines. With the technological advancement in 2020, we have been able to implement all technical innovations and thus the requirements of the modern seam-welded stainless steel roof.

The roof seam welding machines with a cycle frequency of 500 Hz allows optimum welding seams in all operating conditions.

Weld according to ISO 4063 process 22 RRSystem components

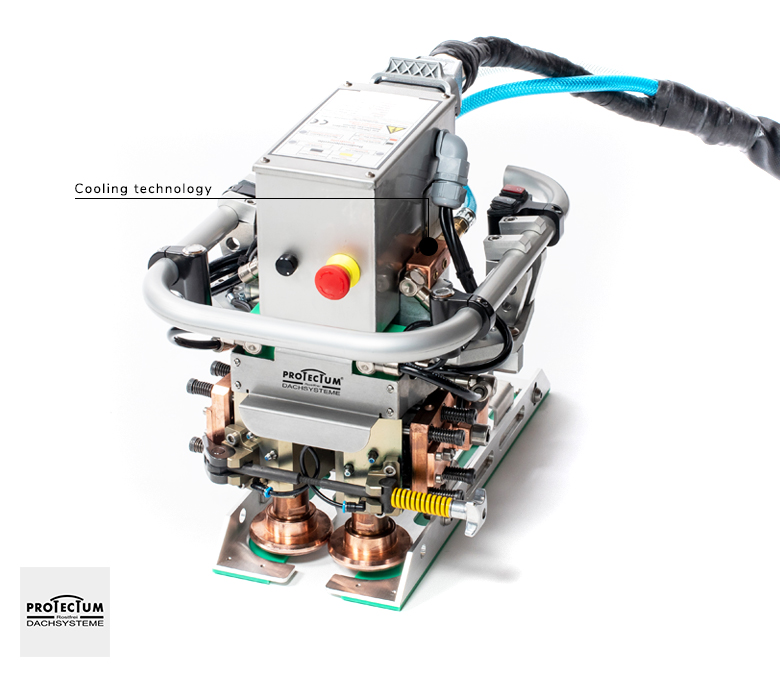

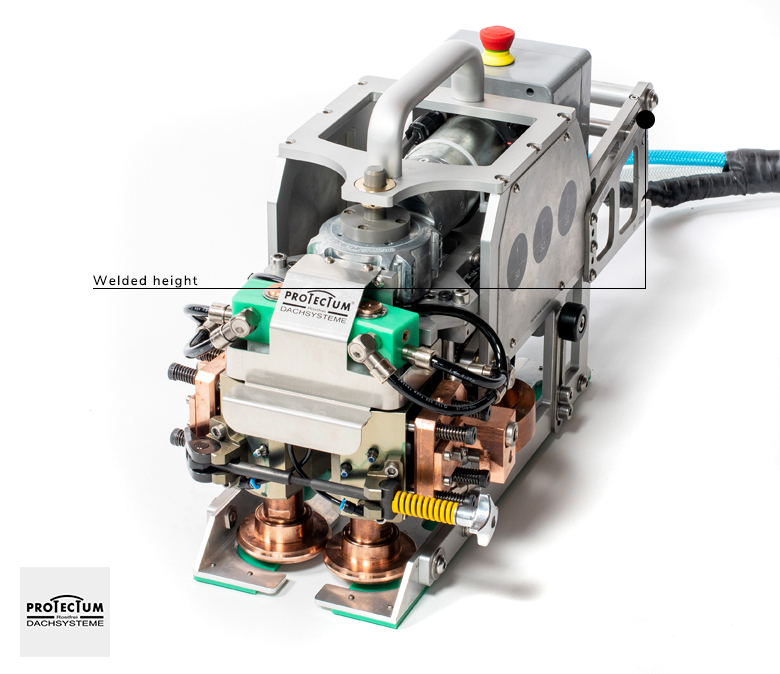

With the Ferumira seam welding machines and its individual components, we offer state of the art technology for the roller seam welding process of standing seams and angle standing seam roofs.

Components of the Ferumira welding machine

- Ferumira Universal

- Ferumira Master

- Ferumira Welding-Inverter-Box

System components

With the Ferumira seam welding machines and its individual components, we offer state of the art technology for the roller seam welding process of standing seams and angle standing seam roofs.

Components of the Ferumira welding machine

- Ferumira Universal

- Ferumira Master

- Ferumira Welding-Inverter-Box

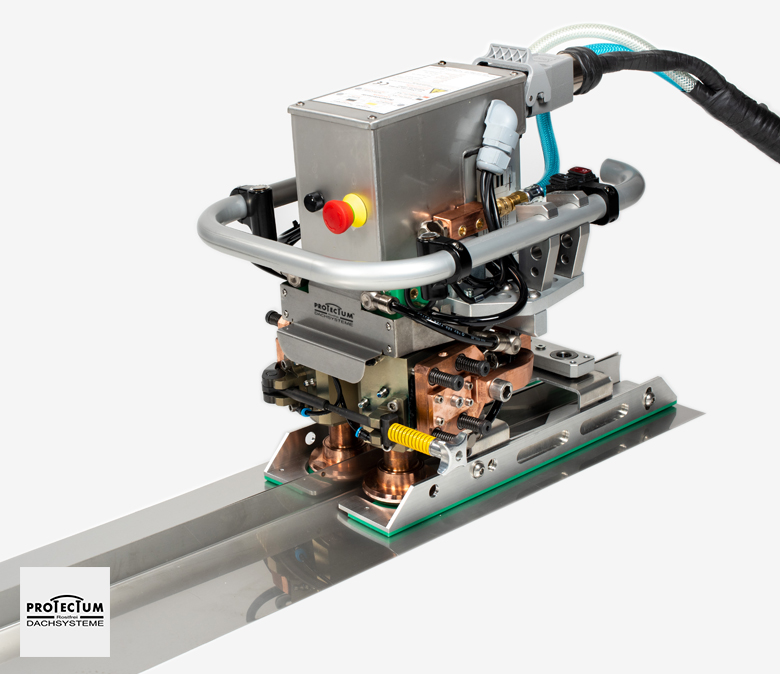

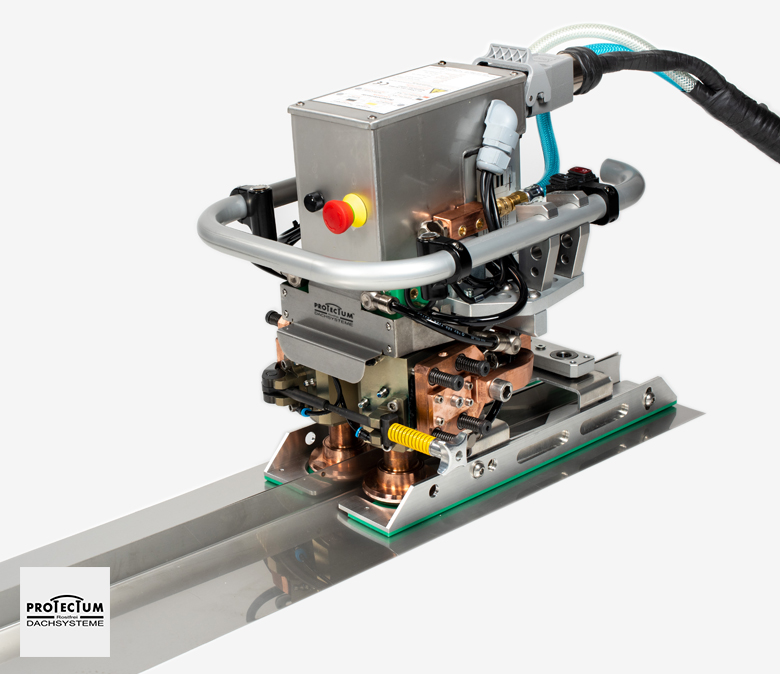

Ferumira Universal

frist step .

Profile welding machine

For the roller seam welding process

at profil metal rails.

second step ..

Adapter slide

With one click from the profile

welding machine to the detail unit.

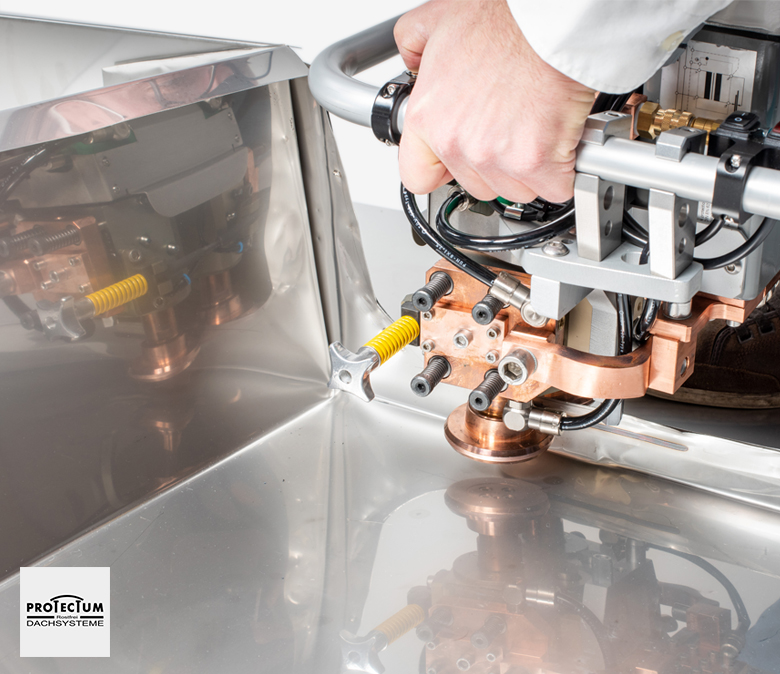

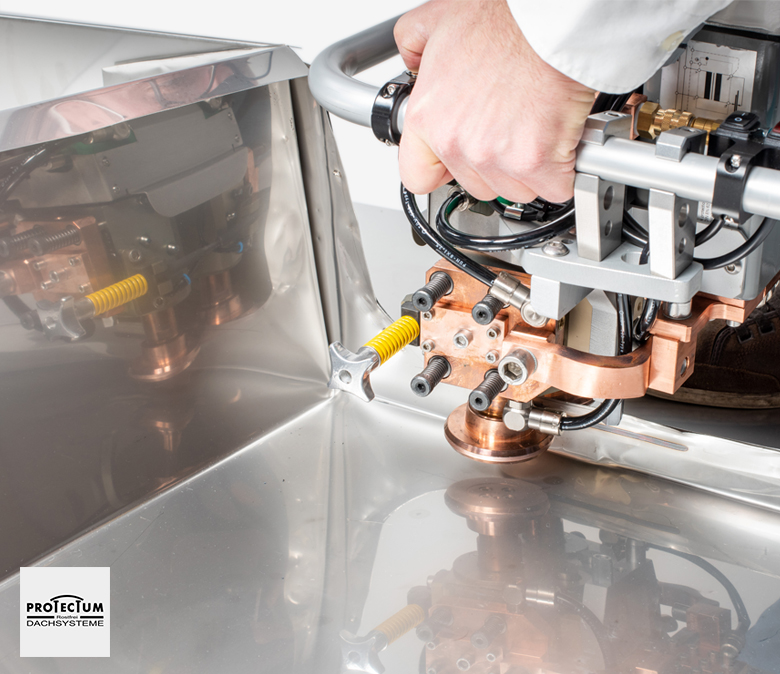

third step ...

Detail welding machine

For the roller seam welding process

at detail connections.

Ferumira Universal

frist step .

Profile welding machine

For the roller seam welding process

at profil metal rails.

second step ..

Adapter slide

With one click from the profile

welding machine to the detail unit.

third step ...

Detail welding machine

For the roller seam welding process

at detail connections.

Facts and benefits

Facts and benefits

Suitable steels

Stainless steel 1.4301

- Thickness

- 0.5 mm

- Description

- EN 1.4301 ASTM 304

- Finish

- extra matt -

brushed - Application

- for fixed roofs with GP6 system clips

- Processing

- according building approval Z-14.1-622

Stainless steel 1.4404

- Thickness

- 0.5 mm

- Description

- EN 1.4404 ASTM 316L

- Finish

- IIIc/2B -

matt rolled - Application

- for fixed roofs with GP6 system clips

- Processing

- according building approval Z-14.1-622

Stainless steel 1.4521

- Thickness

- 0.5 mm

- Description

- EN 1.4521 UGINOX K44

- Finish

- tinned

- Application

- for fixed roofs with GP6 system clips

- Processing

- according building approval Z-14.1-622

Suitable steels

Stainless steel 1.4301

- Thickness

- 0.5 mm

- Description

- EN 1.4301 ASTM 304

- Finish

- extra matt - brushed

- Application

- for fixed roofs with GP6 system clips

- Processing

- according building approval Z-14.1-622

Stainless steel 1.4404

- Thickness

- 0.5 mm

- Description

- EN 1.4404 ASTM 316L

- Finish

- IIIc/2B - matt rolled

- Application

- for fixed roofs with GP6 system clips

- Processing

- according building approval Z-14.1-622

Stainless steel 1.4521

- Thickness

- 0.5 mm

- Description

- EN 1.4521 UGINOX K44

- Finish

- tinned

- Application

- for fixed roofs with GP6 system clips

- Processing

- according building approval Z-14.1-622